UMATECH MICRON - AHMEDABAD

- Home

- Umatech Micron

- Drying

Drying

Drying/Calcining;

Drying is the process of removing moisture/combined water from wet material through heating. Umatech Micron’s batch type and continuous (kiln) type dryers are widely used in minerals, chemicals, Food, and pharmaceutical industries.

Umatech Batch type dryer is charged once with wet material and kept the closed door as long as desired moisture percentage is removed. In this type of dryer , any kind of fuel can be used such as coal, bio-fuel, wood, furnace oil etc. This process is also known as indirect heating, it is because the material is not contact with the supply of direct heat. i.e. first drum is heated and then wet material. This dryer is particularly used where high moisture percentage is in wet material.

This type of dryer has the ability to both mix and dry in one unit offering production benefits that include eliminating the need of handling and interim storage equipment, reducing down time for cleaning and thus reducing production lossed.

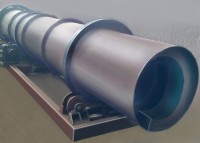

Umatech Continuous (Kiln) type dryer is typically used in the application of when direct heating to wet material and continuous production is required. Material particle is heated through direct contact of hot air or gases, which is passed along the length of the Dryer(Kiln), dt eliminating the heat losses and fuel consumption that is being used in heating the dryer vessel like in batch type dryer.

The selection of the right drying process and dryer design depends on the nature of the materials to be handled here our extensive processing know-how can help ensure customers to select the right equipment for the job; whether that be for the production of a few kilos or multi tonne lots.